Press Release - July 2024

Liquid Hydrogen Void Fraction

Atout Process and ArianeGroup are very pleased to announce the first real time measurements of void fraction in a flowing liquid hydrogen (LH2) feed line, during a flight hardware verification test.

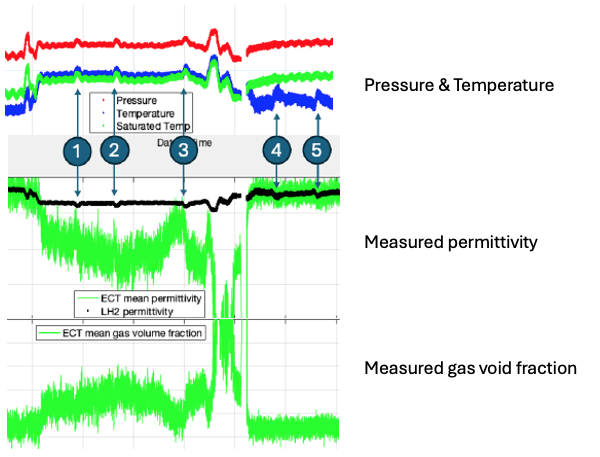

The test used Atout Smart Tanks for Space (SMARTTS) technology in a LH2 transfer line at 22K-24K and 1.5 - 2.5 bar.

The test successfully measured void fraction to +/- 1%, and measured the velocity of injected gaseous hydrogen.

liquid hydrogen flow labelled 1 - 5.

SMARTTS is being developed to provide reliable measurement of propellant mass and distribution under all circumstances including, during ground test, in powered flight, in micro-G, and in any orientation.

Richard Foster-Turner, COO at Atout said “This is a great demonstration of our SMARTTS technology and its ability to measure cryogenic fluid distribution, in real time, in any vessel, which in the case was the main LH2 feed line in pre-flight test.”

Dr. Kei Philipp Behruzi, Senior Expert Thermal & Fluid Dynamics from ArianeGroup said “We are seeking for fill level measurement technologies for cryogenic liquids which also work under microgravity conditions. Atout's technology offers a solution to this challenge. Measuring void fractions in a liquid hydrogen feed line was for us a first relevant application test which was successfully accomplished.”

About Atout Process

Established in 2010 and trading since 2011, Atout has a technology portfolio that includes a range of non-intrusive electromagnetic measurement techniques such as Electrical Capacitance Tomography (ECT), Magnetic Inductance Tomography (MIT), Electrical Velocity Tomography (EVT), and other novel techniques.

Atout develops solutions based on these technologies to solve some of the most difficult measurement problems in industry including food, energy, oil & gas, aerospace and defence. Atout's offering allows customers to see inside pipes and vessels through opaque barriers and to weigh moving product without direct contact.

About ArianeGroup

ArianeGroup is an industrial company delivering critical missions for the space and defence sectors. With 8,300 highly qualified employees in France and Germany, ArianeGroup has unique expertise in access to space, covering the full spectrum of civil and military launch systems, including design, development, manufacturing, integration, flight preparation, operational readiness and end-of-life decommissioning. ArianeGroup is lead contractor for the Ariane 6 European launcher for the European Space Agency (ESA), and for the French oceanic deterrent force M51 strategic missile for the French Defence Armament Procurement Agency (DGA).

Internationally recognised for its innovative, competitive solutions, ArianeGroup has expertise in state-of-the-art technologies, from the chemistry of propellants and composite materials, to liquid, solid and electric space propulsion systems. ArianeGroup also offers a broad range of space, defence and industrial equipment and services, both individually and together with its subsidiaries Sodern, Pyroalliance, Nuclétudes and APP.

In the field of space launchers, ArianeGroup's subsidiary Arianespace markets and operates the Ariane 6 and Vega-C launchers developed for ESA, and its subsidiary MaiaSpace develops and markets the reusable launcher Maia.

ArianeGroup, equally owned by Airbus and Safran, posted consolidated revenues of €2.3 billion in 2023.